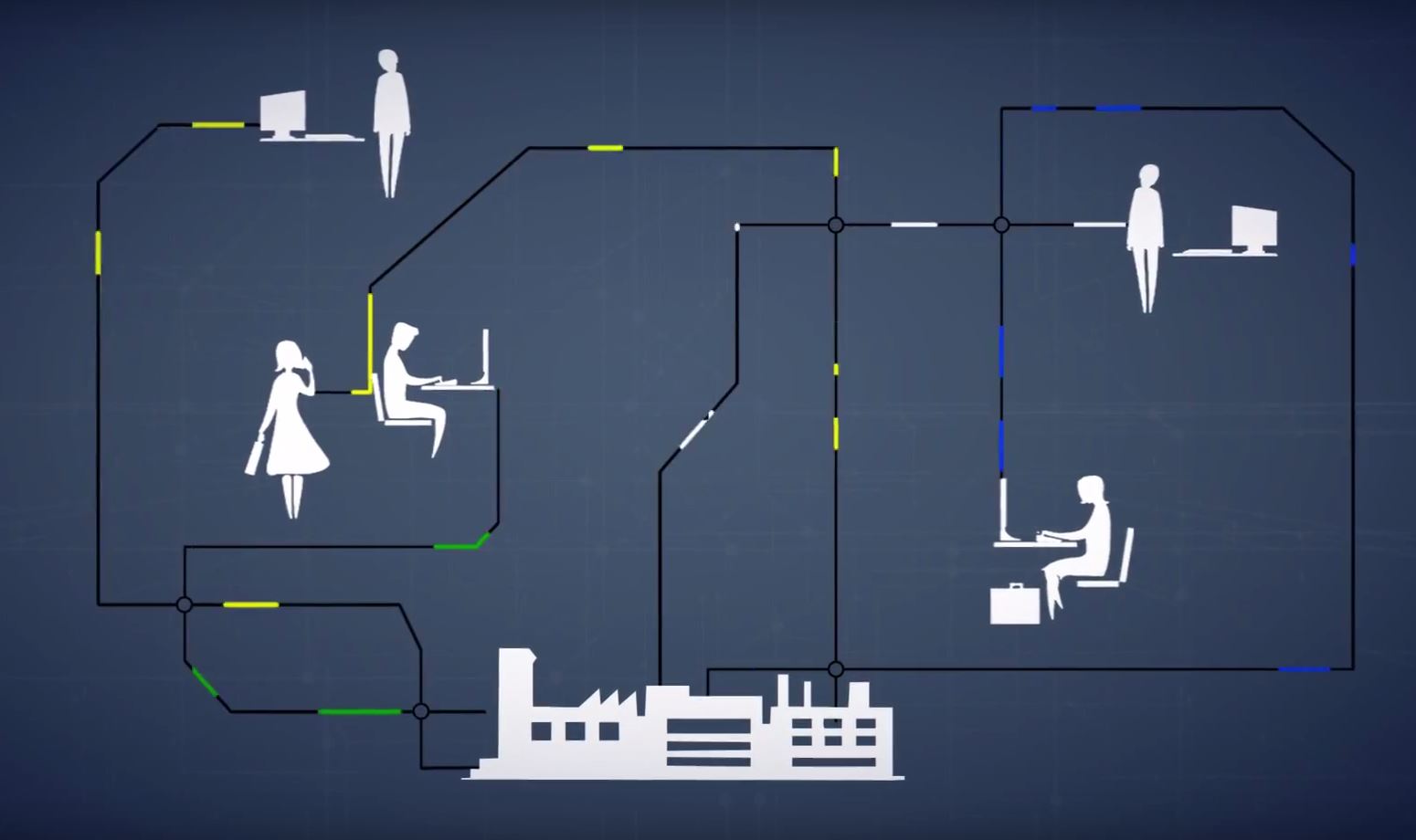

New works, revamping or securing installations: our knowledge of your process and technologies allows us to meet your site’s needs & requirements (safety, optimization, performance commitments, quality, training, etc.).

Our solutions for the chemical industry for instance unite our diverse know-how, for a continuous improvement of your production process and logistics.

-

On-site product storage and transfer

-

Batch process

-

Continuous process

-

Process control rooms